Display problem ? Click HERE

Recommended :

- Subscribe FREE - World Pumpv (USA & Europe only)

- Tips on Succession in FREE Subscription

The discussion on pump cavitation have been circulated around what is pump cavitation ? how destructive a cavitation ? how cavitation sound & looks like ? what the relationship between NPSHa & NPSHr ? how to increases NPSHa to minimize / avoid cavitation ?... We understood that a minimum flow shall be maintained to minimize cavitation, avoid impeller damage and extend pump lifespan. "Rule-of-thumb For Minimum Flow Recycle" discussed few factors possibly determining the minimum flow recirculated around centrifugal pump.

- Subscribe FREE - World Pumpv (USA & Europe only)

- Tips on Succession in FREE Subscription

The discussion on pump cavitation have been circulated around what is pump cavitation ? how destructive a cavitation ? how cavitation sound & looks like ? what the relationship between NPSHa & NPSHr ? how to increases NPSHa to minimize / avoid cavitation ?... We understood that a minimum flow shall be maintained to minimize cavitation, avoid impeller damage and extend pump lifespan. "Rule-of-thumb For Minimum Flow Recycle" discussed few factors possibly determining the minimum flow recirculated around centrifugal pump.

What are the Centrifugal Pump Minimum Flow Control Strategies can be considered ?

There are number ways to implement minimum flow protection strategy for centrifugal pump. Typically they are:

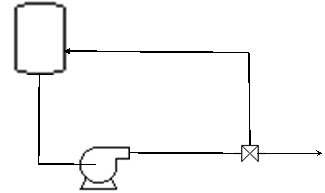

(i) A restriction orifice on pump discharge recycle line

(ii) A flow meter on pump discharge with control valve on recycle line

(iii) Use Automatic Recirculation Valves (ARC) valve

(iv) Flow-Delta P and flow meter on pump discharge with control valve on recycle line

Fig. 1 restriction orifice on pump discharge recycle line

Fig. 2 Flow meter on pump discharge with control valve on recycle line

Fig. 3 Automatic Recirculation Valves (ARC) valve

Fig. 4 Flow-Delta P and flow meter on pump discharge with control valve on recycle

Comparison

The following list out the advantages and disadvantages for above four options

Restriction orifices

- Simple installation

- Maintenance free

- Large pump

- Waste energy all time

- Limit maximum pump output.

Orifice plate in the discharge line

- No continuous recycle thus energy saving

- consumes energy and also slightly reduces pump capacity.

- Using orifice plate to measure flow will results high inaccuracy e.g. minimum flow is 40% of maximum flow, 7% of the set point may be expected.

ARC valve

- Simple & effective

- Lack of flexibility.

- Unstable operation

- expensive

Sketches below show outlook and operation of an ARC valve

- Similar to orifice plate option

- Good option for load sharing of pumps in parallel installation

Restriction orifice option is the most common option adopted in many applications with LOW capacity system and a process engineer is advisable to consider this option. However, for HIGH system and appreciable energy losses is possible, a process engineer is advised to consider flow orifice with control valve option. ARC valve may be a good option to consider if process engineer is well aware of the fluid characteristics and familiar with the operation & dynamic of ARC valve. For very high capacity system and load sharing may be expected, process engineer may consider Flow-Delta P option.

Related Topic

- Quick Check Pump Performance Using Motor Data and Field Measure Current

- Is PumpSmart Right Solution for You ?

- Special Flowmeter & Piping Release...

- Vortex Breaker to Avoid Vapor Entrainment

- Estimate Minimum Submergence to Avoid Vapor Entrainment

- Estimate Pump Power Consumption without Vendor Information

- Trim Centrifugal Pump Impeller for Reduced Head

- Quick Check if Pump Performance Curve (Water) is Good for High Viscosity Fluid

No comments:

Post a Comment